Powerz steam blowers

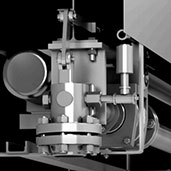

Long retractable sootblower ASO-PG

Application area

Long retractable steamblowers are used for cleaning curtain wall and convective surfaces of boiler units from ash deposits, as well as for cleaning of feed-water economizers and air heaters. Cleaning is achieved by a blowing tube with a nozzle which is partially retained in jacket space of boiler units thanks to kinetic energy of high-speed steam jets with operating pressure of 1-4 MPa and operating temperature of 340-400°С; steam jets are coming out of nozzles towards the contaminated heating surface. Long retractable steamblowers have the cleaning depth of 1.5-12 m.

Installation place

Long retractable steamblowers are used for cleaning platen and convective superheaters and feed-water economizers.

Wall blower ASO-PK

Application area

Wall blower ASO-PK are used for external cleaning of furnace walls throughout the height of the furnace. Surface are cleaned using kinetic energy of steam jet under pressure of 0.8-3 MPa and at operating temperature of 350°С; steam jets are coming out of nozzles towards the contaminated surfaces of furnace waterwalls. When the blower is working, it is cleaning the surface of the wall where it is installed. Extension depth of the water blower is up to 0.5 m. Cleaning area is 360°.

Installation place

Wall blower are used for cleaning furnace waterwalls throughout its height.

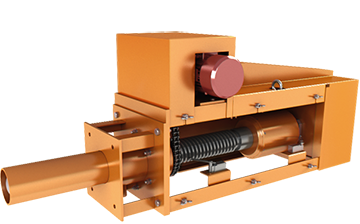

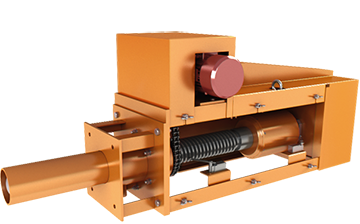

Retractable sootblower ASO-PC

Application area

ASO-PC retractable steam blowers are used for cleaning feed-water economizers and air heaters. Cleaning is achieved by a blowing tube with a nozzle due to kinetic energy of high-speed steam jets with operating pressure of 1-4 MPa and operating temperature of 320-400°С; steam jets are coming out of nozzles towards the contaminated heating surface. Blowing tube is partially retained in the interior space of the furnace. Extension depth of the blower is between 6 and 12 m. Cleaning area is 360°.

Installation place

Feed-water economizers, furnace air heaters

Oscillating sootblower ASO-PM

Application area

ASO-PM oscillating steam sootblowers are used for cleaning of separate segments of heating surfaces. Cleaning is achieved by a blowing tube with a nozzle, which carry out pendulum-like movements, due to kinetic energy of high-speed steam jets with operating pressure of 1-4 MPa and operating temperature of 340-400°С; steam jets are coming out of nozzles towards the contaminated heating surface. Extension depth of the blower is between 1.5 and 9 m. Cleaning area is 360°.

Installation place

Feed-water economizers, furnace air heaters

ASO-PN non-rotating steam blower

Application area

ASO-PN non-rotating steam blowers are utilized for decontamination of heating surfaces. Surfaces are cleaned using kinetic energy of steam jet under pressure of 1-4 MPa and at operating temperature of 340-400°С; steam jets are coming out of nozzles towards contaminated surfaces. A distinguishing feature of this blower is that the blowing tube only carries out translational (and not rotational) movements. Extension depth of the blower is between 1.5 and 9 m. Cleaning area is 360°.

Installation place

Regenerative-type air heater

ASO-PS stationary steam blower

Application area

ASO-PS stationary steam blowers are utilized for decontamination of heating surfaces. Surfaces are cleaned using kinetic energy of steam jet under pressure of 1-4 MPa and at operating temperature of 340-400°С; steam jets are coming out of nozzles towards contaminated surfaces. A peculiar feature of this type of blower is that its blowing tube is fully located in the interior space of the boiler unit and is only engaged in rotational movement. Depth of the blowing tube located in the boiler unit's interior space is between 1.5 and 9 m. Cleaning area is 360°.

Installation place

Feed-water economizers, furnace air heaters

Choice of blower types and parameters as well as blowing protocols is determined by:

• Design of fruance and burner units

• Furnace dimensions

• Contamination intensity

• Nature of contamination

Powerz engineers choose the most relevant blower for each boiler unit. Advice offered by qualified engineers help to make a final choice regarding blower type in order to achieve planned results. Long-lance blowers have extension depth of up to 12 m and are used for decontamination of boiler heating surfaces, furnace waterwalls, feed-water economizers, and air heaters.

Project pictures

+49

+49