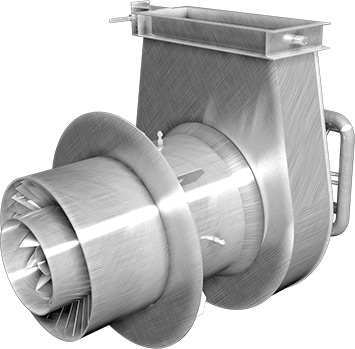

Pulverized coal burners

With extensive expertise in designing energy equipment, Powerz designs and manufactures all types of coal burners with any thermal capacity.

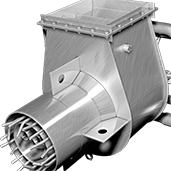

Pulverized coal burners by Powerz comply with all relevant environmental standards and safety and cost-effectiveness requirements. Pulverized coal burners are stocked with ignition devices and sensors which selectively control the burner's torch.

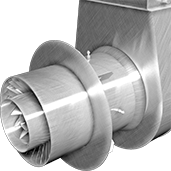

Currently, two types of vane swirlers are used for twisting secondary air: axial and tangential. Depending on parameters determining the quality of coal such as ash, abrasiveness and reactivity, either axial vane or scroll swirlers are used in primary air passages.

| Classification of pulverized coal burners: | ||||

|---|---|---|---|---|

| straight flow vaned | vaned-

vaned scroll- vaned | double flow and

double swirl burners | ||

|

| ||||

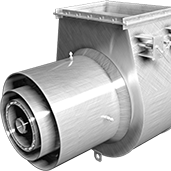

In burners of all three types, high-density pulverized coal is injected through pipes (76 or 89 mm in diameter) with splitters at the end. Central and peripheral air passages have axial swirlers. Natural or coke gas is injected into burners via gas tubes located in series between the adjacent air passages.

Projecting parts of burners influenced by high-temperature combustion gases and radiation are made of heat-resistant materials.

| Technical specifications of GPGK-26 burners | |||

|---|---|---|---|

| Parameter | Bituminous coal

| Natural gas | Fuel oil |

| Burner capacity, kg/h (m3/h) (nominal/maximum) | 4394 | 2034 | 1542 |

| Maximum heating capacity (in MW) | 26,0 | 18,0 | 16,0 |

| Turndown ratio | 2 | 2 | 1,2 |

| Maximum air resistance, kPa | 2,0 | - | 1,0 |

| Maximum natural gas pressure before burner, kPa | - | 15,0 | - |

| Excess air factor | 0,95 | 1,05 | 1,5 |

| Gas temperature, °С | 15 | 15 | |

| Maximum hot air temperature, °С | 428 | - | - |

| Maximum fuel oil pressure before lighting-up burner, MPa | - | - | 0,6 |

| Geometrical features | |

|---|---|

| Burner arch diameter, mm | 816 |

| Overall dimensions (L x H x W), mm

(not exceeding) | 2050х1500х1350 |

| Connection dimensions, mm | 76х6/89х6 |

| Coal:

High-density pulverized coalspreader diameter |

816 120 |

| Air:

central passage peripheral passage |

250х500 500х1000 |

| Natural gas:

Burner weight, kg (not exceeding) | 159х4,5

850 |

| Reliability requirements | |

|---|---|

| Life until discarded: | |

| Basic parts | 200 000 hrs |

| Of them quick-wearing

(nozzles of gas and dust passages) | 15 000 hrs |

| "Recovery time depends on duration of boiler repair Likelihood of failure-free performance" | 0,98 |

| Average life before first overhaul | 4 years |

Due to multitude of fuel types, capacities and applications, Powerz designs and delivers pulverized coal burners which may be operated under custom conditions.

This case describes technical specifications of GPGK 26 burners.

| Passages | Swirler type | Blade angle | Design parameters of twist | Share of total air per burner |

|---|---|---|---|---|

| Central | axial | 40° | 1,64 | 0,194 |

| Peripheral | Axial with profiled blades | 55° | 3,2 | 0,800 |

+49

+49