Gas- and fuel oil burners

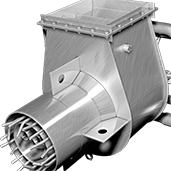

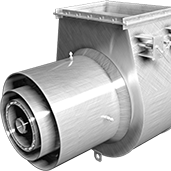

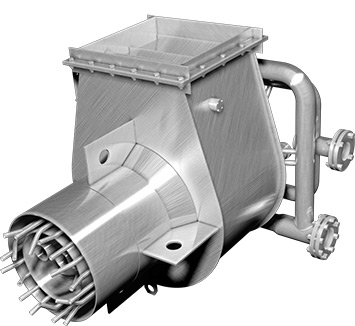

Gas- and fuel oil burners of stationary boilers are intended for burning gas and fuel oil, as well as for full combustion (in combination with furnace) of fuel by creating homogeneous fuel-air mixture.Using rich expertise in designing furnace units, Powerz has designed a range of oil-gas burners. We manufacture straight-flow swirl burners with individual air feed intended for burning liquid fuel and natural gas in furnace units of hot water and steam boilers.

Gas- and fuel oil burners of this type are semi-automatic. This burner is equipped with a fuel oil burner, a peep hole, an ignition signal device and a monitoring sensor of a burner torch. Furthermore, upon request of a client, burners may be equipped with automatic ignition and flame control systems.

| GAS- AND FUEL OIL BURNERS ARE GROUPED: | |||

|---|---|---|---|

| according to

aerodynamic torch design: | according to

the number of separately regulatedair jets: | according to the

type ofair swirler: | according to the

type of gas inlet (gas discharge) device: |

| VORTEX GAS- AND FUEL OIL BURNERS

STRAIGHT-FLOW GAS- AND FUEL OIL BURNERS STRAIGHT-FLOW VORTEX GAS- AND FUEL OIL BURNERS | SINGLE-FLOW GAS- AND FUEL OIL BURNERS

DUAL-FLOW GAS- AND FUEL OIL BURNERS | AXIAL GAS- AND FUEL OIL BURNERS

TANGENTIAL GAS- AND FUEL OIL BURNERS | WITH CENTRAL GAS SUPPLY

WITH PERIPHERAL GAS SUPPLY |

Using extensive experience, Powerz has designed a standard range of oil-gas burner where basic technical features are implemented in an optimal manner. When designing burners for specific boilers, we choose the most relevant burner from the range according to key parameters and then adjust the device in accordance with specific details of the project. This approach helps to effectively use many years of professional experience used during designing of oil-gas burners.

| Basic parameters of oil-gas burners manufactured by Powerz | |||||

|---|---|---|---|---|---|

| Name | Reference | Meaning | Name | Reference | Meaning |

| Turndown ratio | - | 5 | Gas temperature range | °С | 10-40 |

| Fuel: | - | gas, fuel oil | Injection steam pressure | MPa | 0,6 |

| Maximum air resistance in burner, no more than | KPa | 2,0 | Temperature of steam used for injection of liquid fuel, no more than | °С | 200 |

| Nominal pressure near the burner, no more than: | Liquid fuel elasticity near the burner, no more than | сSt | 2,5/16,0 | ||

| Natural gas | KPa | 35,0 | Maximum air excess factor at nominal heating capacity | - | 1,05 |

| Liquid fuel | MPa | 4,0 | Total heat loss after chemical and mechanic underburning at nominal heating capacity, no more than | % | 0,2 |

| Air temperature range | °С | 150-350 | |||

| Basic parameters of oil-gas burners manufactured by Powerz | ||||

|---|---|---|---|---|

| Boiler name | Nominal heating capacity | Nominal flow | Nominal flow | |

| MW | tonnes per hour | m3/h | ||

| GMPV02-5.0 | 5,0 | 0,45 | 566 | |

| GMPV02-7.5 | 7,5 | 0,68 | 849 | |

| GMPV02-10.0 | 10,0 | 0,90 | 1132 | |

| GMPV02-12.5 | 12,5 | 1,13 | 1415 | |

| GMPV02-15.0 | 15,0 | 1,35 | 1698 | |

| GMPV02-17.5 | 17,5 | 1,58 | 1981 | |

| GMPV02-20.0 | 20,0 | 1,80 | 2264 | |

| GMPV02-22.5 | 22,5 | 2,03 | 2547 | |

| GMPV02-25.0 | 25,0 | 2,26 | 2830 | |

|

Natural gas Heating value: Q=39900 kJ/м3 Heating value: Q=31800 kJ/м3 | ||||

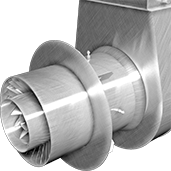

Double-flow burners (air and natural gas). Axial swirler is located in the central passage, and blades are installed at an angle between 45-55° relative to the jet axis. Approximately 40% of air is fed through the central passage, the other 60% is fed through the peripheral (straight-flow) passage.

Burner's gas distribution device has two gas feed flows. Gas is feed through the tubes distributed evenly between central and peripheral passages. Ends of gas tubes have curved heads in order to provide optimal mixture of gas and air and minimize harmful emissions. Suitable materials are used during production of burner nodes and components which are influenced by high temperatures. Burners are equipped with peep holes and tubes for installation of nozzles and ignitors. Installation site of burner torch sensor is determined by the type of a boiler depending on burner design. Parts made of flat steel and carbon steel are used to manufacture burner's air passages (except for nodes and components influenced by high-temperature furnace gases and radiation).

| Designated service life: | |

|---|---|

| Basic parts | 200 000 hrs |

| Quick-wear parts: central passage heads, air swirlers, heads of gas distribution tubes | 12 000 hrs |

| Nozzles | minimum 24 000 hrs |

| Pulverizer and steam nozzle of fuel oil burner | 8 000 hrs |

+49

+49