Automated process control system

Automated firing control system and burner control system

When repairing boilers' burners, adequate level of automation should be provided. Powerz offers two types of burner firing automated control system: basic and advanced.

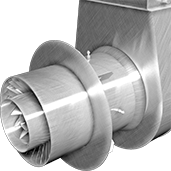

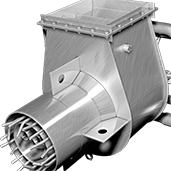

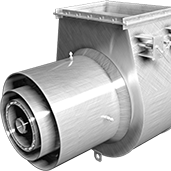

Design of burner devices of boilers. Basic burner firing automated control system is a set of burner control cabinets. Each control cabinet is intended to be used with one burner. Burner control cabinets are installed at service platforms as per РД 12-529-03. Installation should follow the one burner-one control cabinet principle.

Burner 1 | Control

Alarm |

Burner Control Cabinet No N | Control

Alarm |

BOILER UNIT SWITCHBOARD |

Burner No N | Control

Alarm |

Burner Control Cabinet No 1 | Control

Alarm | |

Depending on the facility under repair, requirements on having backup data transfer channels listed in regulatory and documents are taken into consideration during design and production process. When designing the gas part of boilers, control of fuel oil supply duct may be included, if needed.

When redesigning gas-burning units currently in operation, automated process control systems may either control only newly introduced assemblies or fully replace the pre-existing boiler's automated safety control equipment.

| GAS BLOCK FITTINGS REMOTE MANUAL CONTROL (SETUP MODE); | ||

|---|---|---|

| execution of

automated operations: | control and

protection operation: | blocking: |

| • check of burner gas pipeline fittings for gas tightness

• automatic lighting-up of burner • burner shut-down (in emergency or “on demand”) | • burner inflammation failure or flame failure

• ignition torch inflammation failure or flame failure • shutting off the gas supply to the burner if the pressure increases / decreases after the last shutoff device before the burner | • prohibition of gas supply to the burner in absence of a torch flame

• prohibition of closing the solenoid valve on the safety pipeline if the first fast actuating shutoff valve (safety shutoff valve) in direction to the burner is open • prohibition of opening of second safety shutoff valve on the line if the valve on the safety pipeline is open • prohibition of gas supply to the burner if the air damper before the burner is closed |

| Apart from sets of control cabinet for burners, EXTENDED automated process control system possesses master microprocessor control cabinets installed on the boiler switchboard. |

|---|

| This control cabinet is intended for:

• coordination of operation of burner control cabinets • collection of data on burner operation • control of boiler's gas piping fixtures • protection and blocking functions as per РД 153-34.1-35.108 * * "Technical conditions for performing process blocking and protection when using natural gas or fuel oil in boilers in accordance with explosion safety requirements". |

| ON THE FRONT PANEL OF BURNER CONTROL CABINETS ARE MIMIC DIAGRAMS DISPLAYING: | ||||

|---|---|---|---|---|

Voltage |

permission/denialof burner control cabinet operation |

Location of fixturesnear the burner |

Burner operation (signal from torch sensor) |

Information signals on burner control cabinet operation and defects |

+49

+49