Louver & butterfly dampers

Louver & butterfly dampers

Designed as standard, these butterfly dampers are intended to shut off the air flows in the dust, gas and air duct systems of boiler plants and steelplant or petrochemical equipment. Due to the unique design of the flaps, the Powerz manufactured louver & butterfly dampers are 98% gastight, whereas the other butterfly dampers are only 96% gastight. Our louver & butterfly dampers are fitted with external bearing supports which provide improved operational reliability. We offer these dampers with manual drives or with electric or pneumatic actuators. Due to pairwise-counter rotation of the flaps, the Powerz butterfly dampers provide an extended linear range of the flow characteristic and eliminate an asymmetric deflection of the gas flow. The dampers are no less than 98% tight when the flaps are closed. Also, we offer butterfly dampers made of aggressive media resistant materials, or of heat-proof design for temperatures up to 900 C.

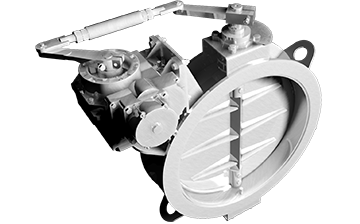

Round butterfly dampers

Application area

Round cross-section butterfly dampers are designed for installation in dust, gas and air ducts.

• The dampers are no less than 98% tight when the flaps are closed.

• Butterfly dampers of round and rectangular sections are fitted with external bearing supports which improve operational reliability.

• We offer these butterfly dampers with electric or pneumatic actuators.

• These dampers may also be offered in two design versions: made of carbon steel for medium temperature up to 425 °C or made of stainless steel for medium temperature up to 585 °C.

• The round butterfly dampers are available within size range from DN 100 mm to DN 7000 mm, and the cornered butterfly dampers are available from 400x500 mm to 5500x5500 mm

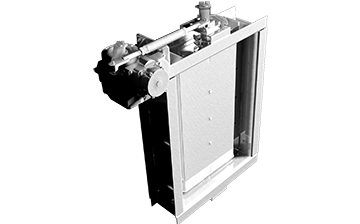

Louver dampers

Application area

Cornered louver dampers of rectangular cross-section are designed for installation in dust, gas and air ducts.

Due to pairwise-counter rotation of the flaps, the Powerz louver dampers provide an extended linear range of the flow characteristic and eliminate an asymmetric deflection of the gas flow. The dampers are no less than 98% tight when the flaps are closed.

Depending on maximum admissible temperature required, these dampers are offered in two design versions: made of carbon steel for medium temperature up to 425 °C or made of stainless steel for medium temperature up to 585 °C.

The flap is driven by an actuator which is mounted on the valve’s body.

The lever system transmits the torque from the actuator to the flap shaft.

+49

+49